Apache NiFi for Industrial IoT: Achieving Real-Time Production Insights

![]()

In modern manufacturing, data flows faster than the product on the assembly line. From robotic arms to conveyor belts, every machine emits a stream of real-time data. But for many factories, that data is either trapped in silos, delayed by manual processing, or worse, completely ignored.

Here lies the irony: manufacturers invest in smart machines, sensors, and control systems, but often lack the digital plumbing to connect them all into a unified stream of insight.

The best fit is Apache NiFi, which is a flow-based data integration platform that bridges operational data from the edge to the cloud. For manufacturers building Industry 4.0-ready plants, NiFi doesn’t just move data; it brings visibility, control, and business value in real time.

This blog explores how Apache NiFi works in Industrial IoT (IIoT), helping manufacturers gain real-time insights and end-to-end visibility into their production lines.

Why Real-Time Production Insights Are Business-Critical

Manufacturing today is about more than just hitting output targets. It’s about staying agile, efficient, and always one step ahead. In industries where every minute of downtime costs money and every process variation affects quality, relying on after-the-fact reporting just doesn’t cut it anymore.

Real-time production insights give manufacturers the visibility they need to act, not react. With the right data at the right time, teams can:

- Reduce downtime by spotting equipment issues before they turn into failures.

- Optimize production by identifying and resolving bottlenecks as they happen.

- Ensure consistent quality by linking live process data to output results.

- Meet compliance standards with complete traceability and automated reporting.

- Shift to predictive maintenance by recognizing patterns in machine behavior early.

This isn’t just about better dashboards. It’s about giving your operations the ability to learn, adapt, and continuously improve, while protecting your margins and growing your competitive edge.

The Industrial IoT Data Challenge

Before diving into solutions, it’s important to confront the real obstacles standing in the way of data-driven manufacturing.

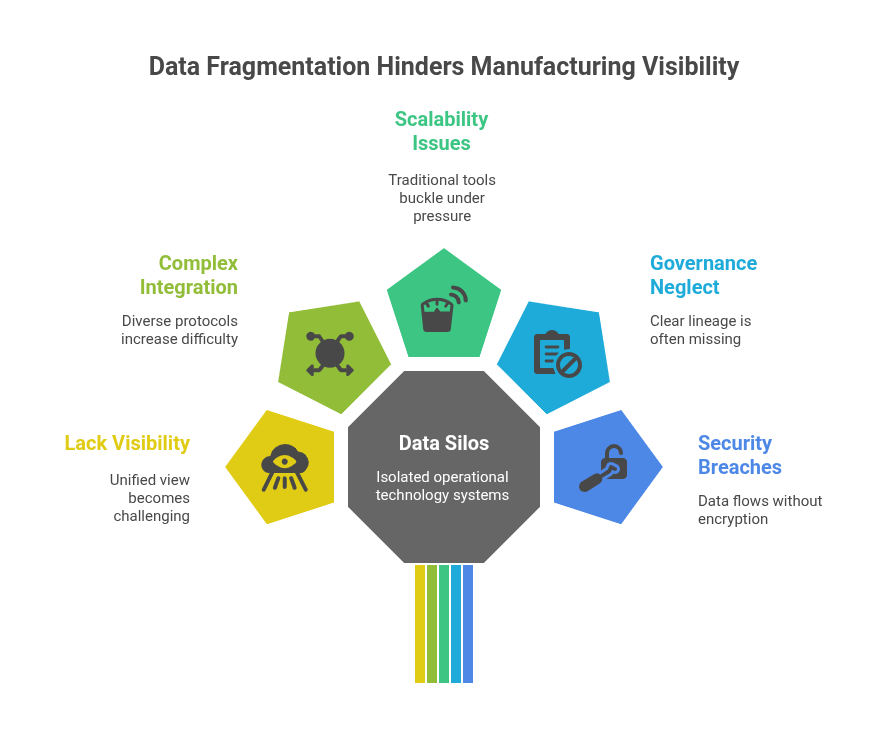

- Data fragmentation is everywhere.

Machines, PLCs, SCADA systems, MES platforms, and ERP tools each operate in their own data silos. They speak different technical languages, making unified visibility a constant challenge.

- Protocol diversity only adds complexity.

From OPC-UA and MQTT to Modbus, REST APIs, and proprietary interfaces, integrating these protocols into a single pipeline isn’t just difficult, it’s time-consuming and brittle.

- Scalability is another major concern.

When you’re pulling telemetry from thousands of sensors across multiple production lines, latency and throughput become mission-critical. Traditional tools buckle under the scale and speed required.

- Data governance often gets left behind.

In the rush to collect and process data, many manufacturers lack clear lineage, audit trails, or transparency into where data flows and how it’s used, leaving them exposed during audits or failure investigations.

- And then there’s security.

Operational data flowing without encryption, access control, or monitoring becomes a gateway for breaches, potentially compromising both IP and plant safety.

The truth is, traditional ETL pipelines were never designed for the dynamic, distributed, and fast-moving nature of the Industrial Internet of Things. What’s needed today is a flow-based data architecture – one that’s built to handle real-time ingestion, protocol variability, scale, and governance, all without sacrificing agility.

Industrial leaders aren’t just looking to collect data anymore. They want to trust it, trace it, and act on it in real time. That’s the new benchmark for operational excellence.

Read More– Benefits of Data Pipeline Automation for Modern Businesses

How Apache NiFi Solves Industrial IoT Integration

Apache NiFi addresses the core challenges of Industrial IoT integration with a platform that’s flexible, scalable, and built for real-time data movement. It’s a bridge between operational technology (OT) and information technology (IT), designed to help manufacturers unlock the full value of their machine data.

1. Flow-Based Programming That Works for Everyone

NiFi’s intuitive, drag-and-drop interface empowers both OT engineers and IT teams to build, manage, and modify data pipelines without writing custom code.

Whether you’re routing temperature readings or filtering vibration data, flows can be designed, tested, and deployed rapidly. This visual approach also makes collaboration across departments simpler and more transparent.

2. Edge-to-Cloud Data Orchestration

With lightweight MiNiFi agents deployed close to the data source, on machines, sensors, or gateways, NiFi can process data at the edge before forwarding it to central clusters or cloud platforms.

This reduces data noise, saves bandwidth, and enables faster, localized decision-making. From the factory floor to your enterprise data lake, NiFi ensures a consistent, secure flow.

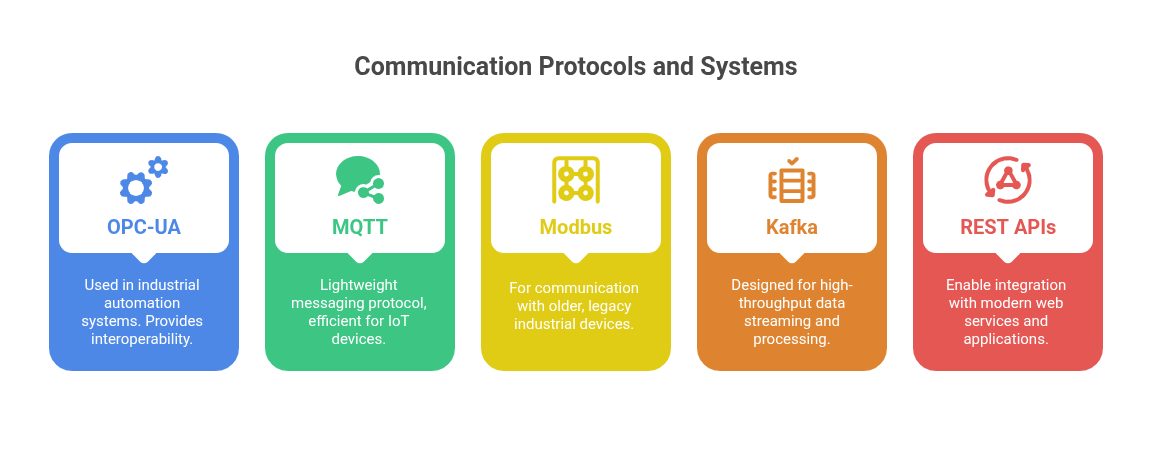

3. Support for Industrial Protocols and Systems

Industrial environments often run on a complex mix of communication protocols. NiFi supports this reality with out-of-the-box or extended support for:

- OPC-UA for industrial automation systems

- MQTT for lightweight messaging

- Modbus for legacy device communication

- Kafka for high-throughput streaming

- REST APIs and other web protocols for modern integrations

This protocol flexibility makes NiFi a powerful translator and orchestrator, seamlessly connecting machines, sensors, analytics platforms, and enterprise systems.

4. Security and Governance Built In

Industrial data is both valuable and sensitive. NiFi includes robust features to protect data and maintain compliance:

- End-to-end encryption (TLS) ensures secure data transit.

- Granular access controls define who can view or change flows.

- Complete data provenance tracks every event, transformation, and movement.

- NiFi Registry provides version control and promotes best practices across environments.

By combining ease of use with enterprise-grade governance, NiFi allows manufacturers to scale safely, without sacrificing visibility or control.

Architecture: A Typical Smart Factory NiFi Setup

Edge Layer (MiNiFi):

- Collects machine data (e.g., temperature, vibration, RPM).

- Filters and compresses payloads.

- Sends only relevant data upstream.

Processing Layer (NiFi Cluster):

- Enriches and routes data.

- Detects anomalies via threshold rules or ML models.

- Pushes actionable data to monitoring dashboards, alerting tools, or cloud platforms.

Cloud/Enterprise Layer:

- Long-term storage (S3, HDFS, InfluxDB).

- Business intelligence tools (Power BI, Tableau).

- Integration with ERP, MES, or CMMS systems.

Best Practices for Using NiFi in Manufacturing Environments

To get the most value out of Apache NiFi in a manufacturing or Industrial IoT setup, it’s essential to design with scalability, reliability, and security in mind. Here are some proven best practices to guide your implementation:

1. Design for Fault Tolerance

Build flows that are resilient by design. Leverage backpressure, retry mechanisms, and failover strategies to handle data surges, connectivity issues, or node failures without losing critical information or disrupting operations.

2. Implement Role-Based Access and TLS Security

Secure your operational data with role-based access control (RBAC) and TLS encryption. This protects sensitive machine and process data from unauthorized access while ensuring compliance with security and regulatory standards.

3. Use Data Flow Manager for Seamless NiFi Flow Lifecycle Management

Simplify how you create, deploy, and manage NiFi flows by using Data Flow Manager. It enables centralized control over your data pipelines, offering AI-powered flow creation, version control, flow deployment & promotion across environments (dev, staging, prod), and complete audit trails – all from a single, unified interface.

4. Monitor with Prometheus and Grafana

Integrate NiFi with Prometheus and Grafana to keep a close eye on system health, data throughput, latency, and error rates. Proactive monitoring helps detect bottlenecks early and ensures high availability of your data pipelines.

Conclusion

In the age of digital manufacturing, the value isn’t in having data-; it’s in using it, in real time, to make smarter decisions. Apache NiFi equips industrial teams to do just that: bridge the gap between machines and meaningful insights.

With the right architecture and partner, NiFi can become the backbone of your smart factory, delivering operational intelligence at machine speed, with business-scale impact.

Looking to build real-time visibility into your production line? Talk to our Apache NiFi experts and get tailored recommendations. Book your consultation today!

![]()